Detailed introduction

Every assembly process of the manufacturing assembly plant needs the warehouse to carry out parts batching and distribution according to the requirements of each process bom. The traditional warehouse adopts manual distribution, which has the characteristics of low efficiency, long response time of distribution, easy to make mistakes in material quantity, difficult to control material quality, etc., so it is difficult to meet the requirements of the next generation of automated manufacturing plant. At present, the automatic storage and self-service in the market The automatic picking and distribution system is suitable for the large batch manufacturing automation system with few parts, single shape and definite quantity, such as automobile, motorcycle, office equipment, home appliances and other automation manufacturing industries. For the aviation manufacturing industry, the automation manufacturing is just starting. The production and assembly of aviation products have the characteristics of small batch, many processes, many types of parts and components, and large quantity differences. The mature distribution system in the market cannot meet the requirements of the aviation manufacturing industry for automatic distribution of materials.

system description

In view of the demand of the aviation manufacturing industry for automatic material distribution, Lianxing company has designed a set of targeted automatic inventory, automatic sorting, automatic counting, automatic detection and automatic distribution automation system, which can realize the functions of automatic distribution of incoming materials into the inventory, automatic picking, automatic counting, automatic detection, automatic batching and automatic picking out of the warehouse. The system can be seamlessly connected with ERP system. According to the ERP system process sheet, BOM sheet, inspection sheet and incoming stock in sheet, the system can realize automatic storage, automatic inspection and automatic distribution, which can greatly save time, save resources, improve production efficiency, effectively control product quality, optimize manufacturing process and optimize management.

system architecture

The system is composed of material inventory and inspection comprehensive functional unit, material transfer device, material storage device, material storage device, comprehensive control system and three-dimensional rack, as shown in Figure 1.

Comprehensive functional unit of material storage, inventory and inspection

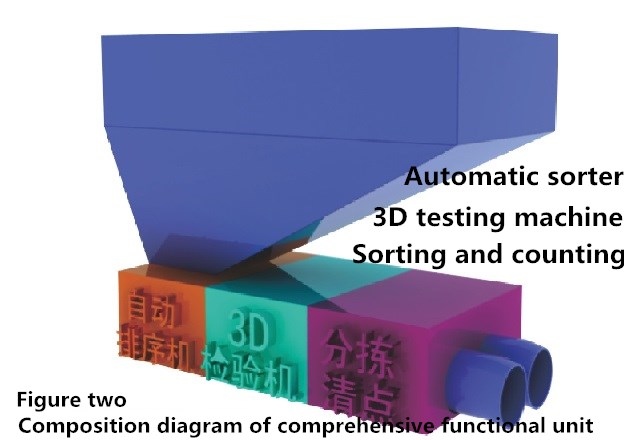

As the core component of the system, the equipment has the functions of incoming material storage, automatic sorting of materials, 3D image size inspection, sorting of qualified products, automatic counting, transfer to the outbound device according to the predetermined quantity, etc. As shown in Figure two.

Three dimensional frame structure

![]() 咨询热线

咨询热线